Gear Pattern Chart

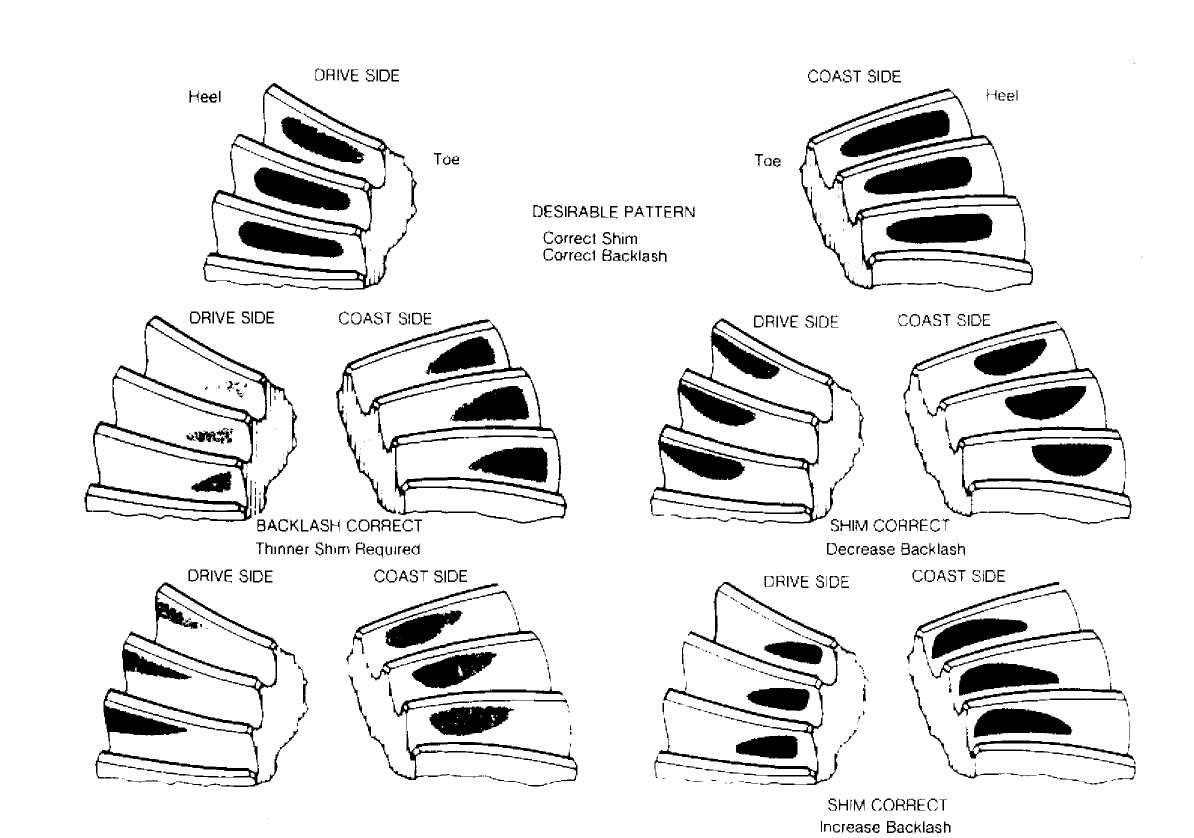

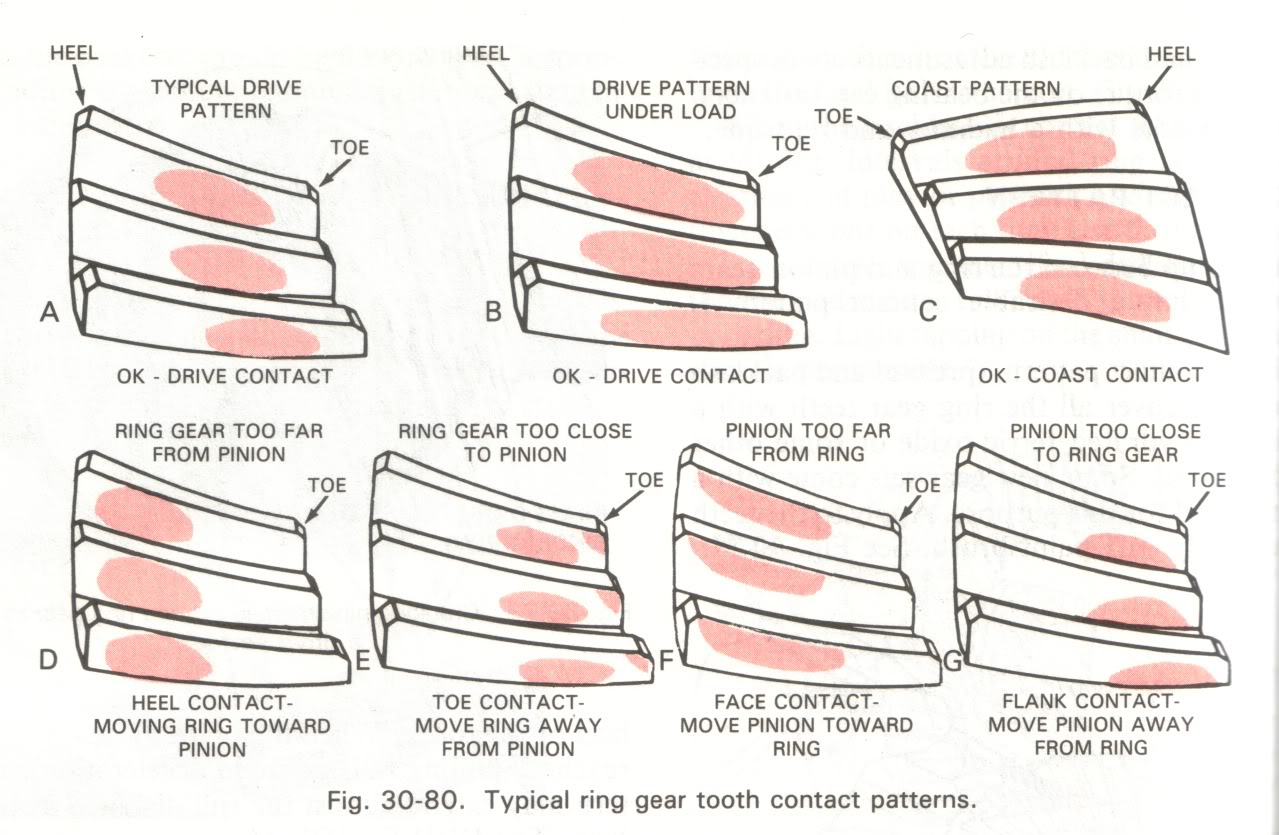

Gear Pattern Chart - Begin by setting proper pinion bearing preload, total turning preload, and ring. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. Web there are three elements involved in determining the best gear ratio: Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an. This is done using gear marking. The heel of the gear tooth is the portion of the tooth surface at the outer end. The length of the pattern in a unloaded condition is. This video was created to give people a basic understanding of. Ensuring peak performance and longevity. Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Web automotive ring and pinion gears must be installed and set up in a very specific way to ensure that they will run smoothly and reliably. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting when looking at th. Web how to create & read ring gear patterns. Web the toe of the gear tooth is the portion of the tooth surface at the end towards the center. Web paint ring gear with marking compound and roll the gear to obtain a contact pattern as shown in the photograph. One is manufactured by face hobbing, while the other one is manufactured by face. The heel of the gear tooth is the portion of the tooth surface at the outer end. While we can’t physically see how the gears actually relate to. Web the pattern refers to how the ring gear and pinion gears mesh. The length of the pattern in a unloaded condition is. Web when setting up the positioning of a ring and pinion in any rear end, there are only two settings that need to be done/measured correctly to ensure proper gear. Web the toe of the gear tooth is the portion of the tooth surface at the end towards the center.. I am now in the process of setting up the gear pattern and shimming the pinion/carrier. Web there are three elements involved in determining the best gear ratio: Web one of the most common questions we're asked is how to properly read contact pattern markings during differential gear setup. The images below illustrate both acceptable and. Web gear tooth patterns. Web in general, pattern movements can be summarized this way: Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an. Yukon provides highest quality drivetrain parts including differentials, axles, driveshafts, super. Swapping in 4.10's to my 8.5 10 bolt.. The length of the pattern in a unloaded condition is. Web there are three elements involved in determining the best gear ratio: Web the heel of the gear tooth is the portion of the tooth surface at the outer end. While we can’t physically see how the gears actually relate to. Web gear tooth patterns are harbingers… they can foretell. The length of the pattern in a unloaded condition is. Web one of the most common questions we're asked is how to properly read contact pattern markings during differential gear setup. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly. The heel of the gear tooth is the portion. Web we can determine how gears mesh by changing how close the pinion gear is to the ring gear centerline. Web automotive ring and pinion gears must be installed and set up in a very specific way to ensure that they will run smoothly and reliably. Web reading and interpreting gear patterns can be very confusing if they aren't obvious. Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Web how to create & read ring gear patterns. Begin by setting proper pinion bearing preload, total turning preload, and ring. Web gm 8.5 gear pattern. Rotate the ring gear several times by hand and inspect the ring. Begin by setting proper pinion bearing preload, total turning preload, and ring. Web one of the most common questions we're asked is how to properly read contact pattern markings during differential gear setup. Web how to create & read ring gear patterns. One is manufactured by face hobbing, while the other one is manufactured by face. Web proper ring gear. The length of the pattern in a unloaded condition is. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly. Web when setting up the positioning of a ring and pinion in any rear end, there are only two settings that need to be done/measured correctly to ensure proper gear.. Web there are three elements involved in determining the best gear ratio: Begin by setting proper pinion bearing preload, total turning preload, and ring. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an. There is a process used. Web the heel of the gear tooth is the portion of the tooth surface at the outer end. Web we can determine how gears mesh by changing how close the pinion gear is to the ring gear centerline. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. Web there are three elements involved in determining the best gear ratio: Ensuring peak performance and longevity. This chart illustrates different patterns and adjustments. One is manufactured by face hobbing, while the other one is manufactured by face. Web automotive ring and pinion gears must be installed and set up in a very specific way to ensure that they will run smoothly and reliably. Web there are two types of gears which are determined by the machining method. Swapping in 4.10's to my 8.5 10 bolt. Web check the tooth contact pattern to diagnose or after installing and adjusting a new ring and pinion gearset. In this video we give a quick d. Web the toe of the gear tooth is the portion of the tooth surface at the end towards the center. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. While we can’t physically see how the gears actually relate to.Gear Diametrical Pitch Chart Jeff Thompson

Differential Gear Patterns

Weber_Ring_Gear_Contact_Pattern_Interpretation.pdf Gear Tooth

How do I fix a thin gear pattern when regearing a rear differential on

Ring And Pinion Gear Pattern Chart

Can You Install Your Own Gears at Home?

Six different gear stick shift patterns. Positions for the gear lever

Gear pattern advice

New Gear Install Need Help Reading Pattern YotaTech Forums

How to Set up Your Rear Gear Correctly RacingJunk News

Gear Tooth Patterns Are Harbingers… They Can Foretell Whether Your Ring And Pinion Gear Set Is Going To Live A Long And Prosperous.

The Heel Of The Gear Tooth Is The Portion Of The Tooth Surface At The Outer End.

I Am Now In The Process Of Setting Up The Gear Pattern And Shimming The Pinion/Carrier.

This Video Was Created To Give People A Basic Understanding Of.

Related Post: