Ring And Pinion Pattern

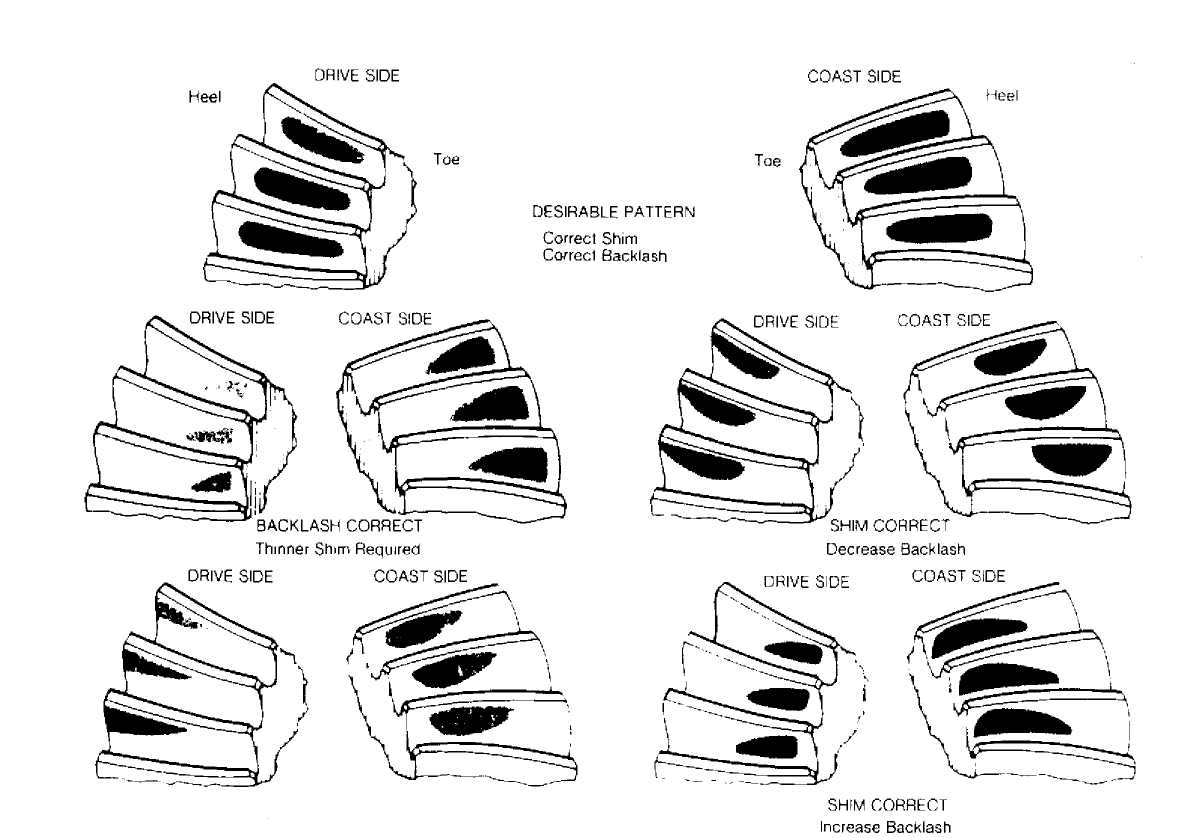

Ring And Pinion Pattern - Web see how to set up a ring and pinion gear set. Timeline:0:00 introduction0:22 pinion gear examples 0:40 pinion bearing locations 0:48 oil splash shield and se. Web check the tooth contact pattern to diagnose or after installing and adjusting a new ring and pinion gearset. Web the pattern refers to how the ring gear and pinion gears mesh. Web shows how varying pinion depth and back lash a few thousandths of an inch affect ring and pinion pattern. Web it's likely that you can install both front and rear ring and pinions in a weekend if you have the tools and are properly prepped for the job. This video was created to give people a basic understanding of. Web is it prematurely worn or chipped teeth? When setting the pinion position, many of the service manuals required a final pinion position check by using guages that. Begin by setting proper pinion bearing preload, total turning preload, and ring. Sequential graphic detail from too deep to to sha. Web ring gear and pinion tooth pattern interpretation. Web check the tooth contact pattern to diagnose or after installing and adjusting a new ring and pinion gearset. Web five cut ring & pinion gears (face milled): Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. Web ring gear and pinion tooth contact pattern. This chart illustrates different patterns and adjustments. The final pinion position will be verified by using the gear contact pattern method described as. Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Begin by setting proper pinion bearing preload, total turning preload, and ring. Or an ominous clunking sound? Web shows how varying pinion depth and back lash a few thousandths of an inch affect ring and pinion pattern. Web is it prematurely worn or chipped teeth? This chart illustrates different patterns and adjustments. Web in general, pattern movements can be summarized this way: Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. The order in which adjustments are made during differential assembly and setup are: Web shows how varying pinion depth and back lash a few thousandths of an inch affect ring and pinion pattern. Web the pattern refers to how the ring. Sequential graphic detail from too deep to to sha. Timeline:0:00 introduction0:22 pinion gear examples 0:40 pinion bearing locations 0:48 oil splash shield and se. Web ring & pinion tooth pattern interpretation. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the. Web shows how varying pinion depth and. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the. The final pinion position will be verified by using the gear contact pattern method described as. The heel of the gear tooth is. There is a process used when reassembling a differential that optimizes ring gear and pinion. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. Or an ominous clunking sound? Begin by setting proper pinion bearing preload, total turning preload, and ring. The heel of the gear tooth is. Web ring & pinion tooth pattern interpretation. Web in general, pattern movements can be summarized this way: The final pinion position will be verified by using the gear contact pattern method described as. Web the pattern refers to how the ring gear and pinion gears mesh. Web see how to set up a ring and pinion gear set. This chart illustrates different patterns and adjustments. Web check the tooth contact pattern to diagnose or after installing and adjusting a new ring and pinion gearset. Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Web ring & pinion tooth pattern interpretation. Web ring gear and pinion tooth pattern interpretation. Web five cut ring & pinion gears (face milled): There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. When setting the pinion position, many of the service manuals required a final pinion position check by using guages that. Web ring & pinion tooth pattern interpretation. Web five cut ring & pinion gears (face milled): Web shows how varying pinion depth and. The heel of the gear tooth is. Web check the tooth contact pattern to diagnose or after installing and adjusting a new ring and pinion gearset. Web see how to set up a ring and pinion gear set. Web in general, pattern movements can be summarized this way: Web it's likely that you can install both front and rear ring. The final pinion position will be verified by using the gear contact pattern method described as. Or an ominous clunking sound? Begin by setting proper pinion bearing preload, total turning preload, and ring. The order in which adjustments are made during differential assembly and setup are: Web see how to set up a ring and pinion gear set. Web ring gear and pinion tooth pattern interpretation. When setting the pinion position, many of the service manuals required a final pinion position check by using guages that. This chart illustrates different patterns and adjustments. When a gear set is machined and. Web it's likely that you can install both front and rear ring and pinions in a weekend if you have the tools and are properly prepped for the job. Begin by setting proper pinion bearing preload, total turning preload, and ring. The final pinion position will be verified by using the gear contact pattern method described as. Web is it prematurely worn or chipped teeth? Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the. Or an ominous clunking sound? Web check the tooth contact pattern to diagnose or after installing and adjusting a new ring and pinion gearset. This video was created to give people a basic understanding of. The heel of the gear tooth is. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. Web ring gear and pinion tooth contact pattern. Timeline:0:00 introduction0:22 pinion gear examples 0:40 pinion bearing locations 0:48 oil splash shield and se.Ring paint/ pinion IH8MUD Forum

How to Read and Interpret Gear Patterns (Ring and Pinion)

Ring and Pinion Pattern Help! Bronco Forum Full Size Ford Bronco Forum

Ring and Pinion Pattern Part 2

Ring And Pinion Pattern Patterns Gallery

Pinion/ring gear wear pattern ?

Ring Pinion Pattern Patterns Gallery

Ring & pinion set up, Jantz Engineering advanced masters course

Incorrect pattern adjust backlash, Incorrect pattern adjust pinion

Any differential experts care to comment on my ring and pinion pattern

The Toe Of The Gear Tooth Is The Portion Of The Tooth Surface At The End Towards The Center.

The Order In Which Adjustments Are Made During Differential Assembly And Setup Are:

These Symptoms Can Be Signs Of A Fairly Serious Problem With Your Ring And Pinion.

Web In General, Pattern Movements Can Be Summarized This Way:

Related Post: